J&D Adjustable Twin Beam Suspended Freestall System

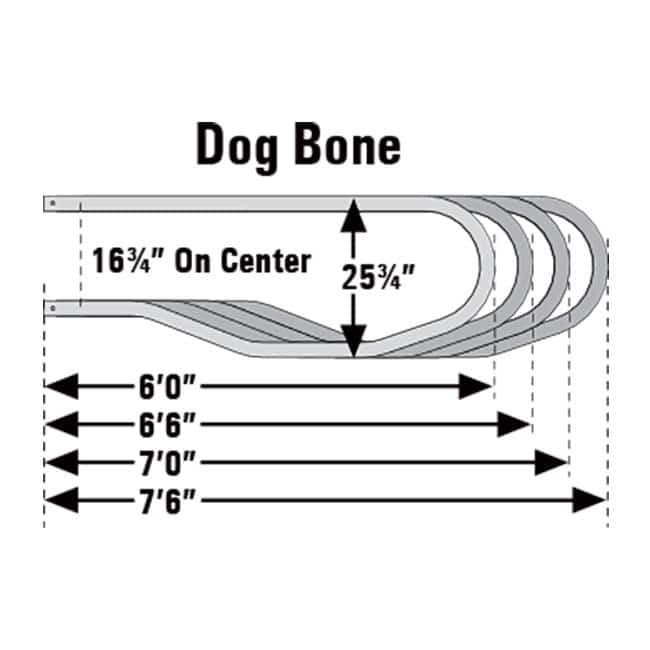

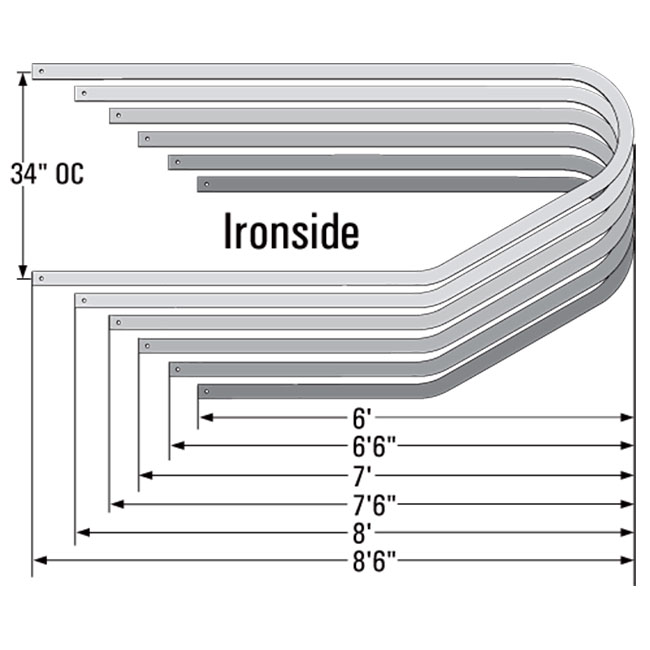

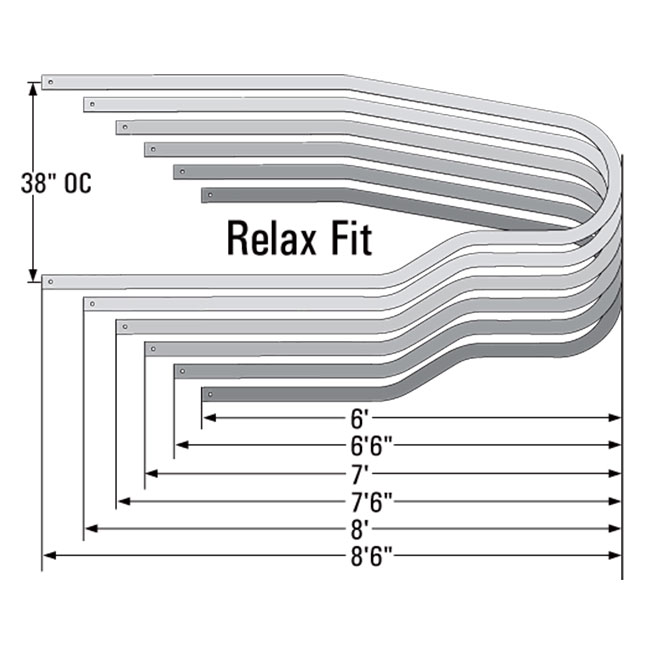

J&D Manufacturing’s popular Twin Beam Suspended Freestall System is now more adaptable than ever before! Cow spacing is fully adjustable along the Twin Beam tubes for more cow comfort area. The Twin Beam height is fully adjustable using the new adjustable post and wall mount. The Twin Beam System uses J&D’s Ironside, Relax Fit, and Dog Bone heavy gauge loops.

J&D Adjustable Twin Beam Suspended Freestall System Features:

- All concrete work can be done without obstructions, saving you money on labor and installation costs

- Stall system stays high and dry for corrosion resistance and longer life

- Head to head and single row installations available

- Compatible with J&D standard Ironside, Relax Fit, and Dog Bone Loops

J&D Adjustable Twin Beam Suspended Freestall System Applications:

Dairy

More Resources:

Product Flyer (PDF)